Metal Steel Stamping chikamu

$4.5≥100Piece/Pieces

| Mutero Wechibharo: | T/T,L/C,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS |

| Min. Raira: | 100 Piece/Pieces |

| Kutakura: | Ocean,Land,Air,Express |

| Port: | NINGBO |

$4.5≥100Piece/Pieces

| Mutero Wechibharo: | T/T,L/C,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS |

| Min. Raira: | 100 Piece/Pieces |

| Kutakura: | Ocean,Land,Air,Express |

| Port: | NINGBO |

Muenzaniso Nha.: RK026

Mutengo: Kst

| Kutengesa Units | : | Piece/Pieces |

| Package Rudzi | : | Bubble mabhegi, cartton, pondo bhokisi |

| Mufananidzo Muenzaniso | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

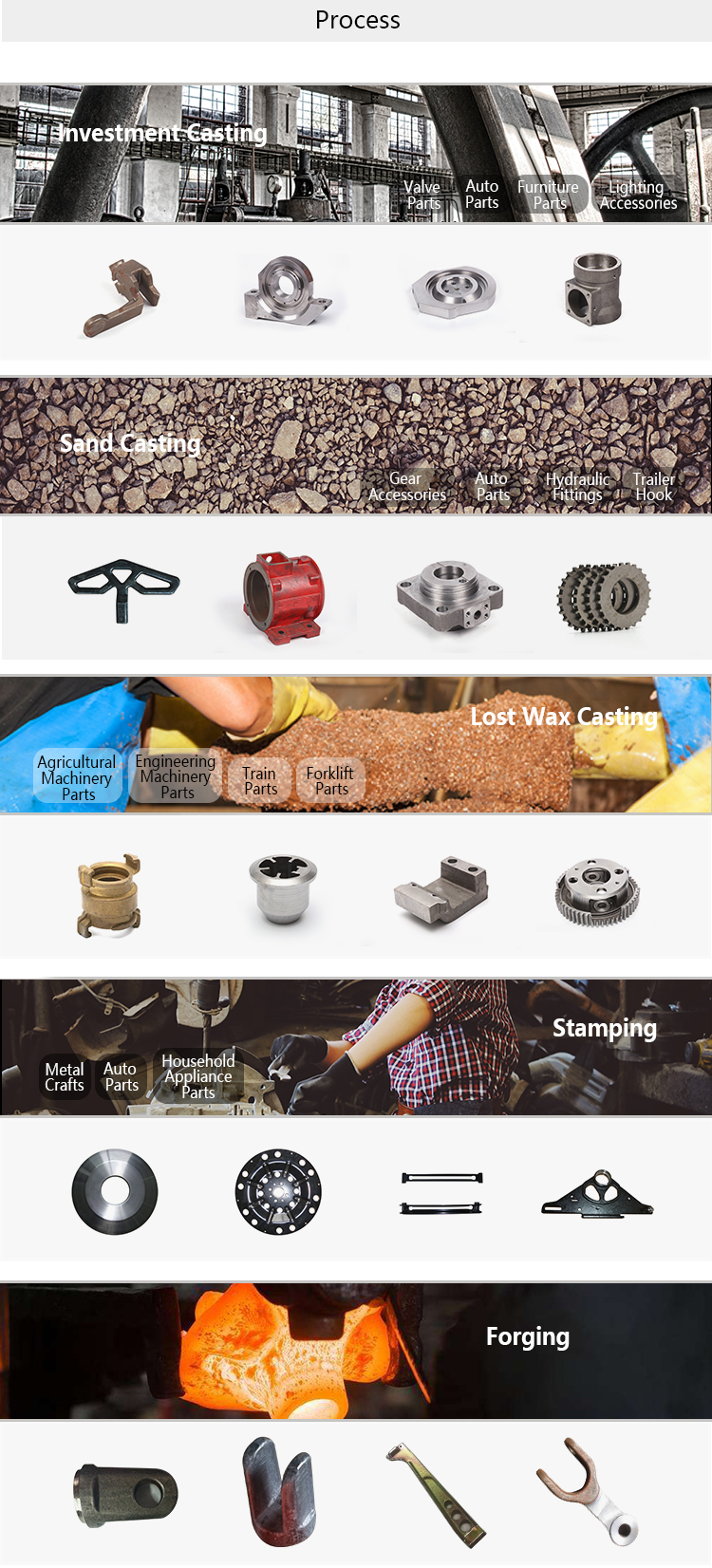

OEM Mugadziri Metal stamping chikamu

Isu tiri kunyatsoziva mukati:

1. Sangweji yekukanda (grey iron, ductle iron, aluminium, nezvimwe.)

2. Investment inokanda (carbon simbi, simbi isina simbi, alloy simbi, nezvimwewo.)

3. Dife casting (aluminium, zinc, nezvimwewo)

3. Machining (CNC Center, CNC Lathe, Lathe, Drilling Machine, Chilling Machine, Pressing Machine, nezvimwewo)

Chitupa: iso9001: 2015, ts16949

Zvikamu zvakaburitswa zvinoshandiswa zvakanyanya mu auto zvikamu: zvekurima, marine; Architectural, Machina, Kurapa; Michina yezvikafu, mavhavha uye zvichingodaro. Izvo zvinyorwa zvataishandisa aluminium; Ndarira; Ndarira; Copper; carbon simbi; Simbi isina simbi uye saka.at panguva imwe chete, tinogona kupa iyo cnc machining; Kufonera; Blacking kugadzirisa; hot dip llvenizing: poda coating: pendi: pleting, musangano wevatengi.

85% zvigadzirwa zvinotengeswa kumhiri kwemakungwa, vatengi vanobva kuAmerican, Canada, Europe Union, nezvimwe.

Ndedzipi mhando dzezvigadzirwa zvatinogona kupa?

| Products | According to the customers'technical drawings or s amples | |||||

| Casting Material | Cast Iron, ductile iron, Grey iron, GG25, GG20, GGG40, GGG50, GGG60 GGG70: | |||||

| QT400-18,QT450-10,0T600-3QT700-2,FCD400,FCD450,60-40-18,65-45-12,ect. | ||||||

| Casting Product Weight | available from 0.02kg to 3000kg | |||||

| Surface Treatment | Oxidation | |||||

| Plating zinc | ||||||

| Painting | ||||||

| Hot galvanized | ||||||

| Powder coating | ||||||

| Electroplating | ||||||

| Sand blasting | ||||||

| Electrophoresis | ||||||

| Vbration Grinding | ||||||

| Inspection | *100% ins pection before shipping, offer the material reports and mechanical property reports | |||||

| *Control Plan and PPAP documents according to the clients'requirements | ||||||

| *ISO9001: 2015 quality control system | ||||||

| Extra Service | CNC machining servce in our machining workshop | |||||

| Advantages | * The dimensions and outs ide shape are similar with investment casting | |||||

| *The surface roughness is good from 2.5 to 25um(100 to 1000um | ||||||

| *The min thickness can meet 3 mm(0. 120inch) | ||||||

| *decrease the internal crack and keep close structure | ||||||

| *As no joint and defect the cleaning and machining work can be less | ||||||

| *it's cheaper because its a simpler process and the foam is cheaper than the wax | ||||||

Chirevo chekuvanzika: Kuvanzika kwako kwakakosha kwazvo kwatiri

Zadza rumwe ruzivo kuti ugone kuwirirana newe nekukurumidza

Chirevo chekuvanzika: Kuvanzika kwako kwakakosha kwazvo kwatiri